View on Willow bank bridge at road level - approach to the bridge.

Willow bank on the approach to the bridge

Willow bank view on the approach to the bridge note - local houses

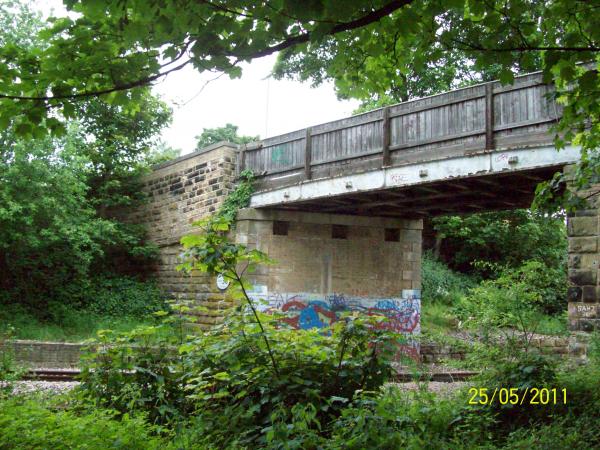

View on Willow bank bridge note cast iron beams and timber parapets.

Electricity cable duct showing in the surfacing.

Willow bank proposed compound area – note trees (willow)

View over the fence to the bridge abutments.

Willow bank viewed from proposed site compound.

Parkland on route to the site compound (public footpath)

Parkland on route to the site compound (public footpath)

Footpath at the access to the site

View on a proposed site entrance (where my car is parked)

View on a proposed site entrance (where my car is parked)

Alternative route under the next bridge on the line.

Dam wall possible crane route into willow bank

Dam wall possible crane route into willow bank.

Trees cut down and site being cleared (Jan 2012 outside bird nesting season)

Trees cut down and site being cleared (Jan 2012 outside bird nesting season)

View on the soffit of the existing structure (timber deck)

View on the soffit of the existing structure (timber deck)

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Night time survey level check + topo survey

Footpath closure- traffic lights start installing drop kerbs

Creating an access into the fields

Creating an access into the fields

Start laying track panels down to the compound

TPA installing track panels down to the compound.

Horse in the field.

Track Panels being installed - with ground levels modified to enable the panels to be laid down.

Site compound – installed cabins in place

YEDL doing electric diversion on Willowbank (south)

YEDL doing electrical diversion north side of the bridge

YEDL doing electrical diversion north side of the bridge

Bridge closed to traffic with diversion route open over the track panels.

Scaffold installed on the four wing walls doing possessions

Wing walls being broken down during normal working

Wingwalls being broken down normal working

Fly tipping!! Scum

Electricity North side cut off ready for bridge removal.

Wing walls being broken down

The old bridge timbers being stripped out during a night shift possession

Surfacing/timbers from the deck stockpiled for removal from site by B&B Demolition.

Surfacing/timbers from the deck stockpiled for removal from site by B&B Demolition.

Timbers on the bridge being removed (Water main to be diverted)

Environmental Screens put in place to reduce the noise from the night works

View of the structure from the site compound

Final section of timbers being removed during the possession

Crane arrived on site ready for rigging up prior to the possession.

Crane rigged – Colin Harwood (temp works designer) arrived on site to inspect temporary works during the installation

Concrete units arrive on site from MaCrete Northern Ireland

Concrete filler beam deck with precast parapet cast integral with the deck.

Concrete impost unit

During the first shift the existing cast iron beams were removed with existing impost units

Existing imposts lifted out

Existing imposts lifted out

Work on abutments from Tower scaffolds note the props at lower levels (total waste of time!!)

Cast iron beams loaded into a skip – Plan A is to break them up for disposal.

Mammoet lifting in the impost units

Impost Unit 4 lifting points - Note Macrete supplied lifters.

Impost Units being installed!

Impost in place dowel bars into holes drilled setting out by D Millar & Mike Lally

Crane lifting the deck units as Grant & Scott set the final bearings an epoxy mortar E

Crane de rigging in the yard.

Works completed crane leaves site.

Cast iron beams- post possession in skip ready problems breaking them with the breaker.

Breaker smashing up the concrete impost units ready for removal off site

Plan B – It was found to be too difficult to break the iron cast beams so they were loaded onto a transport wagon!

New structure- Stitch connection completed between the decks

New structure- Stitch connection completed between the decks

Watermain reinstated through the duct

Approach the south side of the bridge

Temporary access road put in place to connect Willow bank and trackpanels

Approach the south side of the bridge

Wingwalls being rebuilt, ducts installed and filler board joint in place

Wingwalls being rebuilt, ducts installed and filler board joint in place

View from the wingwall – not scaffold being removed water division under the track

Waterproofing in progress on the bridge deck - Proctors Waterproofing.

In situ concrete cope formwork set up on the wingwall ready for concrete

Concrete cope cast and formwork removed and sand carpet - laid on the bridge deck.

Note lifters on parapets are still to be filled

Surfacing being laid on the bridge deck

Surfacing plant parked up ready to do the surface course.

Brickwork and wingwalls completed with scaffold removed

View on the new structure complete with scaffold removed and drainage down pipes installed

Track panels being lifted now that the structure is open to the general public

Demolition materials being cleared from site.

View on the completed bridge Deck

View on completed structure at deck level

View of the outside face of the bridge with scaffold removed

Existing weight signs need to be removed

Site access prior to being returned to the original layout

Site compound removed panels removed - fences still to be reinstated.

Track panels removed - area grass seeded

Track panels removed and area grass seeded

View on the new bridge fences to be reinstated

View over the new bridge deck fully open to the general public.

Pallisade fence reinstated – grass in the compound started to return

Site access blocked off with a bund and new timber fence installed

Site access blocked off with a bund and new timber fence installed

View on the completed structure from at track level

View on the completed structure at deck level.

View on the completed structure at deck level.

View on the new structure looking at the parapet and wing walls fully reinstated.

Access at Willow bank - fence replaced and blocked off.

Route of the track panels grass growing in on the route with minimal grass seeding.

View on the completed structure at track level

Trees planted to replace those removed due to the bridge replacement works.

Fencing installed + new willow saplings planted infront of the fence.

View on the completed structure from track side.

View on the completed structure fully open to traffic.

Principal Contractor – Birse Rail

Client – Network Rail

Engineer – David Millar, Mike Lally

Commerial – Chris Wortley

Foreman – Grant Toesland

Trees/Fencing – ASB fencing

Track panels – TPA

Site cabins – A Plant

Waterproofing – Proctors Waterproofing

Temporary Works Checks - PASCO

Scaffold – SYS

Demolition – B&B Demolition

Labour Stane/Brickwork – APB Group ltd

Tools/Equipment – Speedy

TM – David Skells TM ltd

Bearings – SK Bearings

Timber crane pads – Marwood

Surfacing – South Yorkshire Tarmac

|