|

| Home |  | |  | Project 24 Barrow Hill Demolition | |

|

|

|

Existing Barrow Hill Bridge and Footbridge.

View looking under the existing footbridge (to be retained) + Barrow Hill bridge to be demolished.

Existing bridge - Span to be underfilled with foam concrete.

Side span - 1st lift of foam concrete - retained with mesh reinforcement and polythene.

Polythene sheet inside the mesh reinforcement ready for foam concrete.

Next lift of underfill being set up for concrete.

Foam concrete place as underfill to the 3rd Lift.

Completed underfill last lift poured through holes punched in the deck.

View on the completed underfill.

Temporary works installed to retain the fill on the existing wingwall. The new structure under construction of the end of the wingwall.

New structure under construction - once this bridge is open then Barrow Hil Existing bridge can be demolished.

Existing bridge open to traffic under traffic lights.

Existing Eckington Road being planned out - with the new road fully open.

Existing services - cables being recovered from the existing bridge area.

Underfilled section of the existing structure being backfilled and buried.

Electricity cable being "spiked" with a bullet through the cable.

Underfilled structure being backfilled and buried.

Surfacing being removed from the existing bridge deck - Note the existing gas main on the bridge still "live" blue line.

Crane platform being created between the new and existing structure ready for a 100t crane.

New Gas Main being installed across the new bridge deck.

New Gas main being made "live". Note the existing main has been drilled at tapped to ensure that it is empty of Gas.

Parapet being demolished on the bridge deck.

Excavtor pulling in the parapets and clearing the deck.

Parapet removed - SGB combi-safe fence erected on the edge.

Gas Main removed final section of cables being ripped out and cleared from the deck.

Double team - excavators on the bridg pulling in the Southern Parapet.

Parapet pulled over and pulled in - Not one brick landed on the track.

Dene Illingsworth - Senior Foreman - installing edge protection Combi- safe.

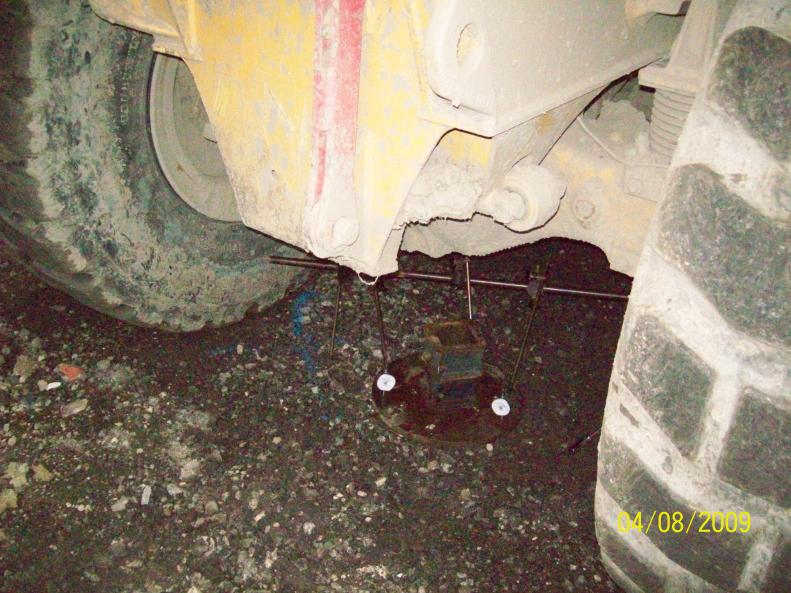

Plate load test on the crane platform - using the ADT axle.

Polyethene sheeting laid on the track - Holemaster start cutting up the deck panels.

Deck slabs being cut up - lifting holes for the chains drilled in the bridge deck.

Holemaster - cutting the bridge deck up.

Portable drilling rig being used for finishing the holes on the deck.

View on the underside of the bridge deck - looking at holes for lifting points.

Ends of the slabs fully exposed. Fall arrest system set up on the bridge deck.

100T Crane set up lifting out the precast units.

Pre-cast units being lifted out - Note the chains in the lifting holes.

Crane lifting pre-cast units from the deck.

Cranes - stacking up the units on the bidge deck.

David Millar on the last unit getting ready to lift it out.

With the final section removed the crane was de-rigged ready for the next visit.

2nd crane visit - 10t lift cross beam being lifted free.

Cross beam being lifted free - note the dowels on the underside.

Holemasters - using a Bandsaw to cut through the legs of the trestle.

1st Trestle set up for lifting. Holemaster cutting the trestle legs.

Cut free trestle being lifted on to the deck.

2nd Trestle being cut free.

Band Saw cutting the trestle legs free.

Trestle cut and lifted out.

Last trestle being cut free for lifting.

Completed cutting works last trestle gets lifted out.

Trestle and header beam laid out on the bridge ready for removal.

View on the abutment ready for remodelling - note the string line on the wall showing the cut line.

Track saw being used by Holemaster to cut a saw line on the abutment wall.

Saw cut on the existing abutment - scaffold erected to enable the final section to be cut.

Ivor King Movax rig removing the sheet piles from the wingwall.

Braithwaite demolition clearing the trestles of the bridge deck.

Parapets being removed on the arch span approach.

Parapets removed from the arch spans.

Arches being broken down.

Central arch span being broken down.

Works progressing across the arch spans.

Arch being broken down - note the ash infill and just how loose the bricks in the arch are as it is broken free.

Abutment concrete cill beam being removed - two excavators being used to pull it over - Note the plywood protection on the track.

Abutment being pulled over and broken down.

Bricks broken down and loaded away to the crushing yard.

Bridge abutments removed - bricks cleared up.

Abutment cut and the top section of abutment pulled back.

Crane lifting in the Stone cop stones - scaffold being used for access.

Crane used with rock skip - operatives breaking out the final 500mm depth of the trestle legs.

Profile of the new canal being formed - view on the pallisade face.

View on the canal bed - sheet pile and cop wall - pallisade fence.

Pallisade fence installed on the North abutment.

Completed new bridge with finished fences - bridge fully removed.

Page under construction...

| |

| | |

|

|

|

|

|

|